Mica

What is Mica?

Mica is an alumina silicate mineral mainly among its varieties. It stands out for its flexibility and elasticity when exfoliated, as well as for its shine. It is one of the minerals with the greatest presence in the earth’s crust and is found mostly in igneous or metamorphic rocks. It is a mineral that has many varieties that are classified as white and black micas. Biotites and muscovites are the most common and contain, in addition to aluminum, other elements such as potassium (in biotite and muscovite) or magnesium and iron (only in the case of biotite).

It is a mineral that has a hardness between 2 and 4 on the Mohs scale (between 2 and 2.5 in the case of muscovite), high resistance to high temperatures (melting point at 1540 ºC) and a density of between 2.7 and 3.0 g/cm³.

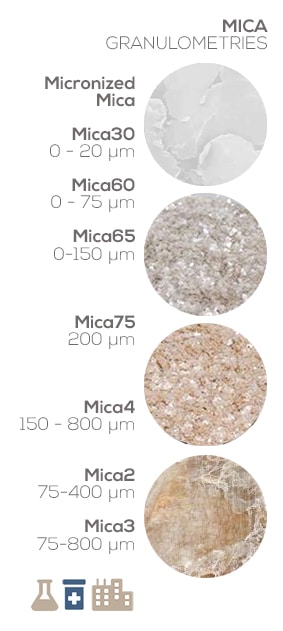

Available variants

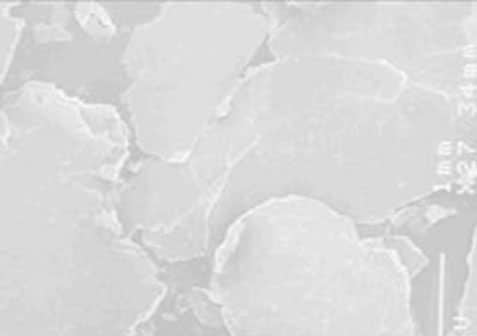

MICA 30, 60 AND 65 MICRONIZED

Material up to 150 µm granulometry. Mica30 between 0 and 20 µm, Mica60 between 0 and 75 µm and Mica65 between 0 and 150 µm. It is a micronised product with a high degree of whiteness.

MICA 75

Material up to 200 µm granulometry. It is an intermediate product between micronised micas and those with a greater granulometry.

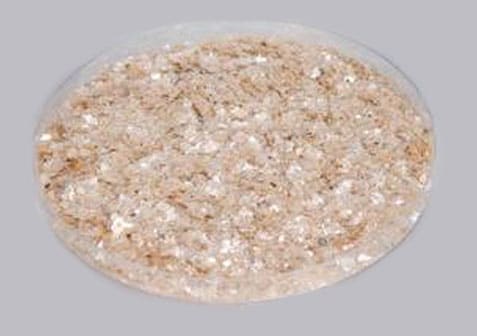

MICA 4

Material between 150 and 800 µm of granulometry. It is a product with a very low bulk density, with values below 0.40 g/cm³. Mica4 is ideal for applications in which you want to use it as a filler in the manufacture of lightweight materials.

MICA 2 AND 3

Material with a granulometry between 75 and 400 µm in the case of Mica2 and between 75 and 800 µm in Mica3.

Mica is supplied in different particle sizes and degrees of whiteness, to satisfy consumer requirements.

What is Mica used for?

The properties of elasticity, flexibility and thermal, electrical and water resistance of mica make it a mineral that perfectly adjusts to many of the needs of various industrial sectors. One of its greatest applications is its use as electrical and thermal insulation in high-voltage machines, electric motors, generators, condensers, and in ship and building construction. Some types of mica withstand high temperatures that reach up to 1200 ºC, maintaining their properties in a stable manner. It is also used, to a lesser extent, in the chemical industry for the manufacture of cosmetics, paints, adhesives, and sealants.

Coatings and paints

Mica is used as a pigment extender in paints to provide greater resistance to water penetration, and in other types of coatings and linings.

Adhesives, resins and sealants

Mica is used in the manufacture of sealant and adhesive materials and products. Mica has various applications in construction, such as in the manufacture of thermal, electrical and waterproof insulation. It is also used as reinforcing filler in the manufacture of certain putties and plasters for the construction of lighter materials with less risk of cracking.

Plastic compounds

Mica is used as an additive and reinforcement in the manufacture of certain polymeric compounds. Its elastic, flexible and heat-resistant properties make it a good choice for making thermally and electrically insulating plastic components.

Cosmetic and medical

Mica is a non-toxic mineral that can be applied to the skin in various cosmetics and makeup products. Provides a shimmering effect and adds a natural shine to products.

Supplies

Muscovite mica can be supplied in different particle sizes depending on the type of product desired: 0-20 µm, 0-75 µm, 0-150 µm, 0-200 µm, 150-800 µm, 75-400 µm or 75 -800µm.

For different applications, one size or another is recommended.

It can be supplied in 25 kg bags (on 1,000 kg pallets) or 1,000 kg big bags.

To request a quote please, contact us.

OFFICE

08013 BARCELONA – Spain